The SP-2 Smart MIG has two MIG torches that can be setup for two different base metals: Aluminum and Silicon Bronze or Steel. The shielding gas and weld program with the appropriate synergic curve automatically switch when pulling the trigger. The SP-2 is ideal for body shops welding stainless steel and aluminum. In synergic mode, the microprocessor controls optimal arc stability and weld quality. Welding can be done in continuous or pulse mode. Maximum power output of 200 A.

Auto Switching

To switch welding different base metals, simply pick up the appropriate torch and pull the trigger. The microprocessor and weld programs do the rest.

MIG Welding

Features two MIG welding torches and two wire spools. Also includes preloaded weld programs and synergic curves for all the common welding situations in automotive repair.

Pulse MIG Comparison

The main difference between the three pulse MIG series welders is the number of torches.

SP-2 | SMART MIG

AUTO SWITCHING

Simply pick up the appropriate torch for the base metal you want to weld and pull the trigger — the SP-2 will automatically switch the weld program and synergic curve — no need to change wire spools or shielding gas.

MIG WELDING

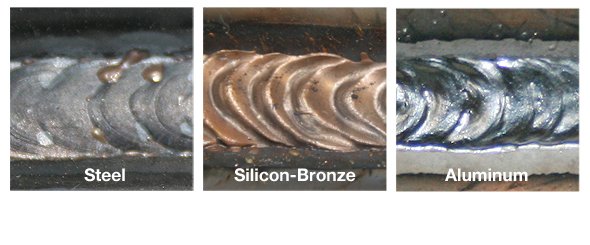

Preprogrammed synergic curves maintain optimal arc stability and weld quality.

SP-5 SMART MIG

Single phase 208-240V 50-60Hz

5 torches — 3 MIG, 1 TIG, 1 stick

3 wire spools

2 gas cylinders

SP-2 SMART MIG

Single phase 208-240V 50-60Hz

2 torches — 2 MIG

2 wire spools

2 gas cylinders

SP-1 PULSE MIG

Single phase 208-240V 50-60Hz

2 torches — 1 MIG, 1 stick (TIG Optional)

1 wire spool

1 gas cylinder

TECHNICAL SPECIFICATIONS

Input Voltage:

Single Phase

208 - 240V 50-60Hz

Amps / Volts, Min - Max:

20A / 15V - 200A / 24V

Protection:

IP 22

Insulation:

H

System Weight:

154 lb. (70 kg)

FEATURES

2 Torches

2 Wire Spools

Pulsed Welding

Continuous Mode

Inverter Technology

Preloaded Synergic Programs

Easy Feed Wire System

Auto Switching